|

|

PDF MIL-DTL-5541F Data sheet ( Hoja de datos )

| Número de pieza | MIL-DTL-5541F | |

| Descripción | CHEMICAL CONVERSION COATINGS | |

| Fabricantes | ETC | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de MIL-DTL-5541F (archivo pdf) en la parte inferior de esta página. Total 12 Páginas | ||

|

No Preview Available !

NOT MEASUREMENT

SENSITIVE

MIL-DTL-5541F

11 July 2006

SUPERSEDING

MIL-C-5541E

30 November 1990

DETAIL SPECIFICATION

CHEMICAL CONVERSION COATINGS

ON ALUMINUM AND ALUMINUM ALLOYS

This specification is approved for use by all Departments and Agencies of the Department

of Defense.

1. SCOPE

1.1 Scope. This specification covers chemical conversion coatings formed by the reaction

of chemical conversion materials with the surfaces of aluminum and aluminum alloys.

1.2 Classification. The chemical conversion coatings are of the following types and

classes.

1.2.1 Types. The chemical conversion coatings are of the following types (see 3.1):

Type I – Compositions containing hexavalent chromium.

Type II – Compositions containing no hexavalent chromium.

1.2.2 Classes. The materials, which form protective coatings by chemical reaction with

aluminum and aluminum alloys, are of the following classes (see 6.1 and 6.4).

Class 1A - For maximum protection against corrosion, painted or unpainted.

Class 3 - For protection against corrosion where low electrical resistance is required.

Comments, suggestions, or questions on this document should be addressed to: Commander,

Naval Air Warfare Center Aircraft Division, Code 491000B120-3, Highway 547, Lakehurst,

NJ 08733-5100 or emailed to [email protected]. Since contact information can

change, you may want to verify the currency of this address information using the ASSIST

Online database at http://assist.daps.dla.mil.

AMSC N/A

AREA MFFP

Free Datasheet http://www.Datasheet4U.com

1 page

MIL-DTL-5541F

3.7 Electrical contact resistance of class 3 coatings. Electrical contact resistance testing

shall be as specified in the contract or order (see 6.4). The test method, frequency of testing, and

required resistance values shall be specified by the acquisition activity to meet the needs of a

particular application (see 6.1.2.1).

3.8 Chemical analysis of the conversion solution. Chemical analysis of the conversion

solution shall consist of concentration, pH, and temperature evaluations to determine that the

bath is within the ranges specified by the chemical manufacturer (see 6.11).

3.9 Workmanship. The chemical conversion coatings covered by this specification shall be

produced by treatments and processes that produce coated components as specified in this

specification.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are

classified as follows:

a. Process control inspection (see 4.2).

b. Conformance inspection (see 4.3).

4.2 Process control inspection.

4.2.1 Process control tests and solution analysis. Test specimens shall be tested in

accordance with table I and 4.2.1.1. In addition to the tests in table I, solution analysis shall be

performed on all the processing solutions in the chemical conversion line (see 3.8) to verify that

the chemical concentrations are within ranges established for optimum performance (see 6.11

and 6.14). Process control tests are conducted to determine compliance of the chemical

conversion coatings with the requirements of this specification and are acceptable as evidence of

the properties being obtained with the equipment and procedures employed.

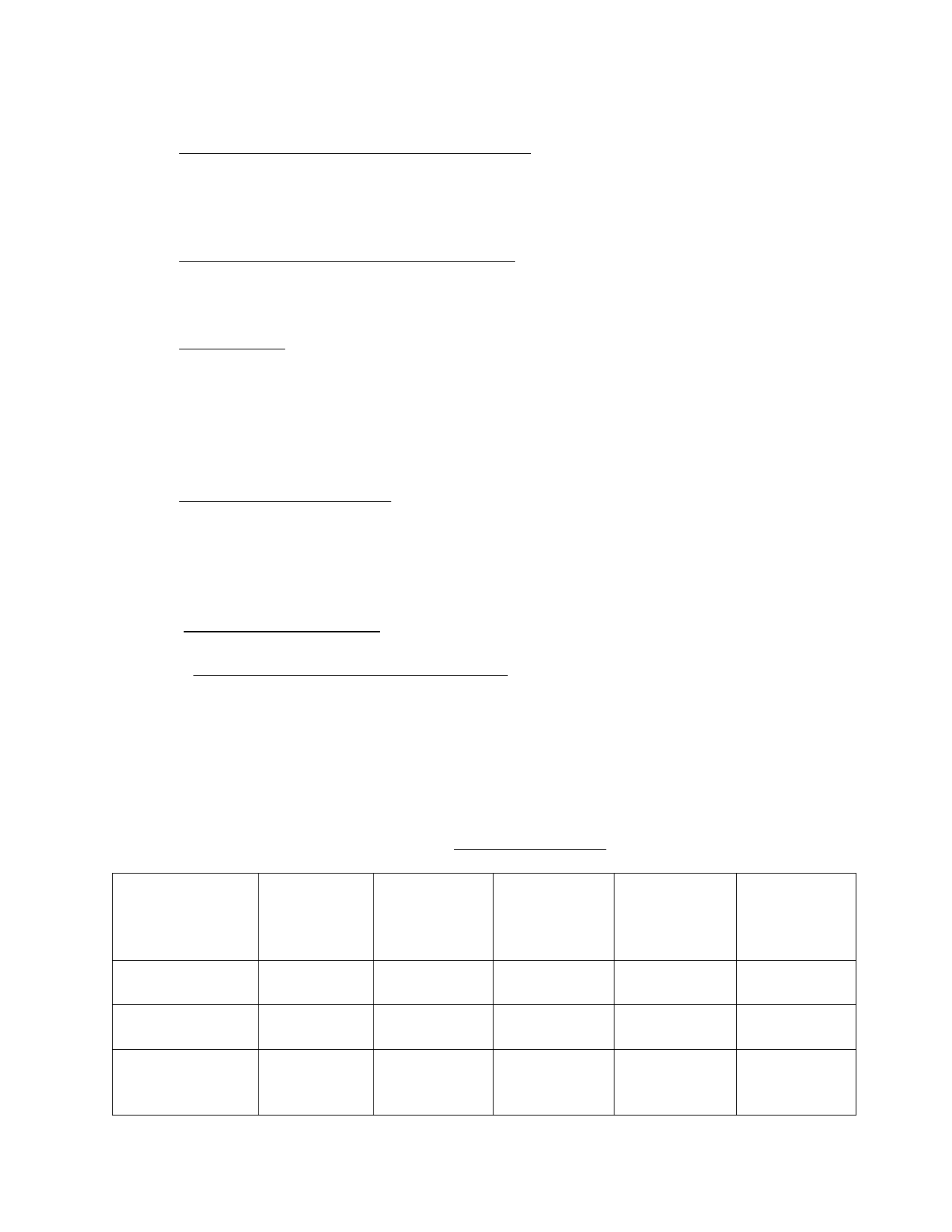

TABLE I. Process control tests.

Tests

Corrosion

resistance

Wet tape

adhesion

Electrical

contact

resistance

Class

1A

3

1A

3

3

Number of

test

specimens

5

5

2

2

5

Test

specimen

preparation

paragraph

4.2.2

4.2.2

4.2.2-4.2.2.1

4.2.2-4.2.2.1

4.2.2

Requirement

paragraph

3.6.1

3.6.1

3.6.2

3.6.2

3.7

Test

paragraph

4.4.1

4.4.1

4.4.2

4.4.2

4.4.1

5

Free Datasheet http://www.Datasheet4U.c

5 Page

MIL-DTL-5541F

type I materials, existence of a coating can be verified by using a simple spot test specified in

ASTM-B449. For type II materials, existence of a coating should be verified per the

manufacturer’s recommendation

6.9 Determination of a corrosion spot or pit. As a general rule, a corrosion spot or pit

usually displays a characteristic tail or line, however, any visible corrosion or pitting except

scratches or substrate surface defects is to be counted..

6.10 Test specimens (2024-T3). Due to high copper content, 2024-T3 aluminum alloy test

specimens are more susceptible to salt spray failure than 6061-T6 aluminum alloy test specimens

(see 4.2.2).

6.11 Chemical analysis of the conversion solution. Note that many conversion materials do

not react sufficiently with aluminum surfaces at low temperatures. Conversion coating of parts

in an unheated facility, such as a hangar, during colder periods of the year is not recommended.

6.12 Paint adhesion. Coated parts should be allowed to dry in accordance with the

chemical manufacturer’s recommendation before they are subsequently painted or adhesion

failures may occur. When coated parts are stored for extensive periods before painting, they

should be cleaned in accordance with 3.2 to reactivate the surface by removing dust particles.

Excessively thick coatings may result in paint adhesion problems, such as blistering, due to

higher amounts of soluble material under the paint.

6.13 Paint compatibility. Compatibility problems between conversion coatings and certain

Chemical Agent Resistant Coatings (CARC) have been reported.

6.14 Temperature effects on corrosion protection. Unpainted conversion coatings will

commence losing corrosion resistance properties if exposed to temperatures of 140 ºF (60 ºC) or

higher, during drying, subsequent fabrication, or service. As temperatures and exposure times

increase, the corrosion protection of unpainted conversion coated parts decreases. The reduction

is believed to result from the coating dehydrating and the resulting insolubility of the chromates

within the coating.

6.15 Solution analysis documentation. Documentation of the history of each processing

bath, showing additions of replenishing chemicals to the bath and the results of all solution

analyses performed must be maintained. Testing of the solution should be consistent with best

industry practices and manufacturer’s recommendations. Upon request of the acquisition

activity, such records, as well as reports of the test results, should be made available. These

records must be maintained for not less than one year after completion of the contract or order.

6.16 Shelf life. This specification covers items where shelf life is a consideration. Specific

shelf-life requirements should be specified in the contract or purchase order. The shelf-life

codes are contained in the Federal Logistics Information System Total Item Record. Additive

information for shelf-life management may be obtained from DoD 4140.27-M, Shelf-life

11

Free Datasheet http://www.Datasheet4U.com

11 Page | ||

| Páginas | Total 12 Páginas | |

| PDF Descargar | [ Datasheet MIL-DTL-5541F.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| MIL-DTL-5541F | CHEMICAL CONVERSION COATINGS | ETC |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |